Colour laser marking is not a recent process but was founded 10years back, although barely utilized. The Color Marking technique was originally noticed as a promising tool for marking craft metal and jewellery. Over the years we notice this method in a tremendous market as manufacturers of consumer goods are glancing for fresh strategies with promising output differentiation.

The technique of colour marking entails a variety of elements which comprises titanium and stainless steel. Additionally, broadening the parameters of a laser about the colour application. This strategy can bring about a monotonous item refreshed with shades of colour, that could be of vast benefit.

What is Colour Marking?

Colour laser marking, or colour laser inscribing as it’s widely known, is the manner of the colour upswing to an item that is being inscribed. “Marking” is the more qualified word since engraving wipes out a fraction of the material’s body, formulating a cavity.

Utilizing colour for laser marking or engraving enables you to broaden your potentials and deliver extra versatility in your commodity offerings, as well as appealing characteristics for your clients.

Colour laser engraving can be toppled into two subsets, that colour laser engraving on metal and colour laser marking on the plastic item. You can refer to this website for further information.

Colour Laser Marking on Plastics

As of this procedure, colour laser markings for plastics is still exclusive, but lately, progressive processes may rapidly alter that across the business. At prevailing times, plastic substances that are inscribed remains in the identical colour as the actual original stuff, with fixed alternatives in light and dark shades.

Colour Laser Engraving on Metals

Colour engraving metal has more comprehensive abilities and applications, with laser colour marking stainless steel being extremely prominent in a lot of enterprises. This pattern of marking alters the surface coating of the element and can generate different colours on the article.

Applications for Colour Laser Engraving

Companies have operated colour laser engraving and marking for various objectives, such as through:

· Personalizing commodities for customers

· Adding graphics, designs, and images to modify an output

· Improving their branding skills by marking a piece with their company colours

· Ornamenting craft metal works, watches, and jewellery

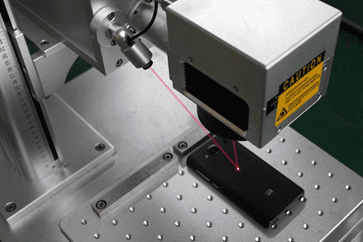

· Marking cameras, mobile phones and other electrical equipment

· Marking metal fittings in the bathroom to denote hot and cold water

· Marking parts for use in medical products, automobiles, aircraft, and more

· Marking firearms and knives for personalization

Difference between Laser Marking, Engraving and Laser Etching

All three processes are very prominent, three of these laser assistances furnish a lasting marking solution, fulfilling regulations and amplifying distinction to your commodities and parts.

The distinction between laser marking, laser engraving, and laser etching primarily have to do with what each technique does to the marking surface, involving how intense the laser gets on and how it remakes the all-around impression.

Laser marking discolours the surface of the item, whereas laser etching and engraving eliminate a fraction of the surface area as it marks. The major difference between laser etching and engraving is the depth to which the laser penetrates the surface.